guide d'application sur la mise en place d'un programme de contrôle qualité des pipettes

guide sur le calibrage, la maintenance et le contrôle qualité des pipettes

Contenu du document

Introduction

De nombreux systèmes et normes de qualité, tels que les bonnes pratiques de laboratoire (GLP), les bonnes pratiques de fabrication (GMP) et la série ISO 9000, exigent une procédure de maintenance et de calibration régulière et documentée pour tous les instruments. Certains laboratoires, en particulier les laboratoires accrédités, nécessitent également une calibration régulière des pipettes dans une installation de calibration accréditée ISO 17025 afin d'assurer la sécurité et la traçabilité des résultats.

Programme de contrôle de la qualité des pipettes

Pour répondre aux exigences réglementaires et des systèmes de qualité, les laboratoires doivent mettre en place un programme documenté pour le contrôle de la qualité des pipettes pendant leur utilisation. Un programme suggéré basé sur les meilleures pratiques industrielles comprend les éléments suivants :

- Routine de test en laboratoire avec contrôle régulier de la performance des pipettes

- Calibration et maintenance régulières des pipettes réalisées dans un laboratoire de service accrédité

Routine de test en laboratoire

- Les pipettes sont vérifiées en utilisant une balance ou un photomètre et les erreurs systématiques et aléatoires sont calculées à partir des résultats, comparées aux limites d'acceptation et enregistrées

- La fréquence des tests est basée sur les risques associés à l'utilisation des pipettes

- Le matériel nécessaire inclut une balance de 4 ou 5 décimales, des pointes jetables, de l'eau déionisée ou des solutions colorantes, un thermomètre, et un baromètre

- Les critères d'acceptation devraient être définis par le fabricant de la pipette ou l'ISO 8655

- Les résultats des tests doivent être documentés et les pipettes qui ne répondent pas aux critères d'acceptation doivent être marquées et retirées de l'utilisation

Programme de calibration et de maintenance

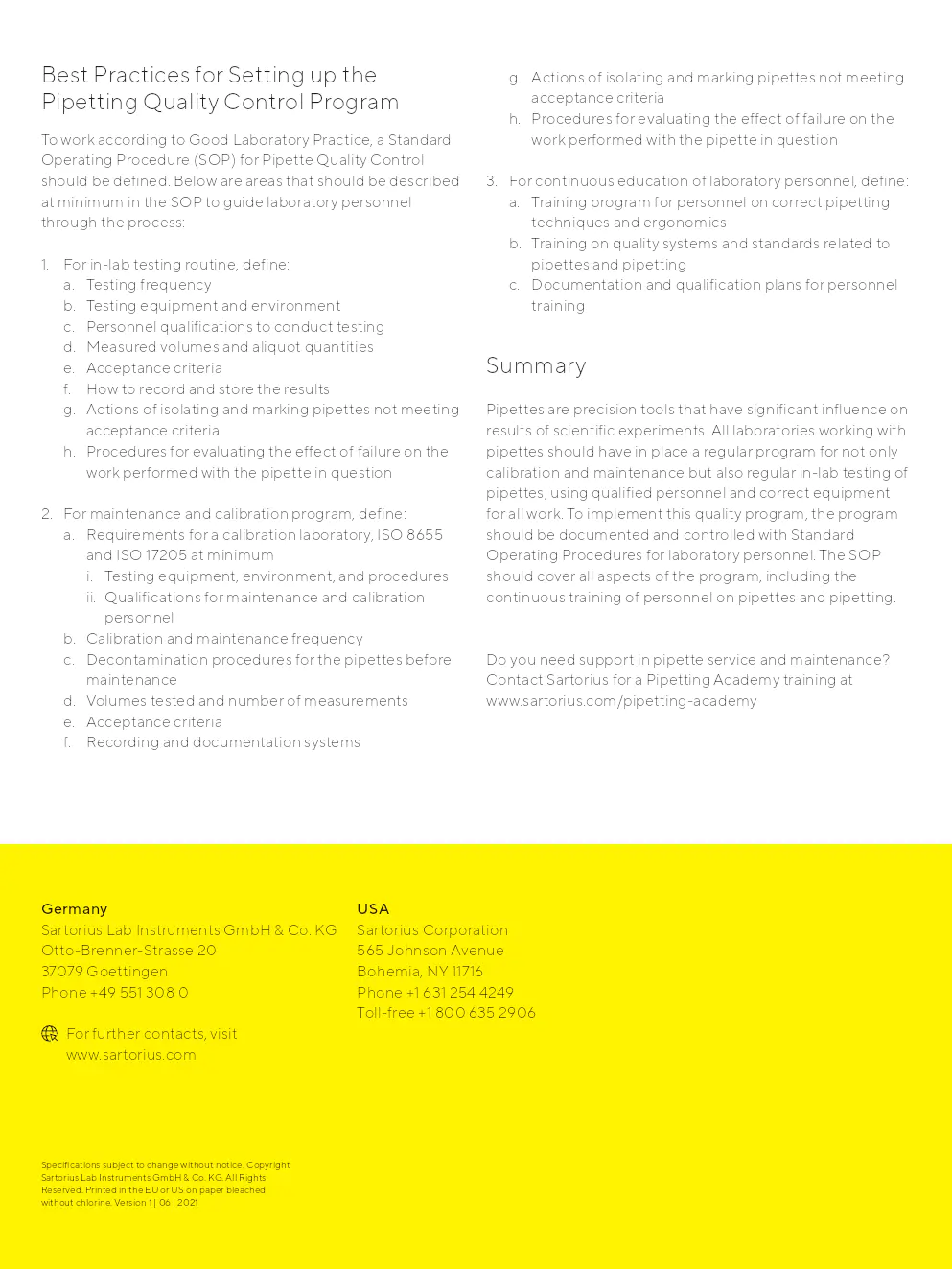

- Les pipettes doivent être entretenues selon les instructions du fabricant, ce qui inclut le nettoyage, le graissage et le remplacement des pièces usées

- Les critères d'acceptation pour la calibration devraient inclure des mesures à plusieurs volumes avec calcul des erreurs systématiques et aléatoires

- Le programme de calibration et de maintenance doit fournir des enregistrements documentés de toutes les activités de maintenance et de réparation, ainsi que des certificats de calibration

Meilleures pratiques pour la mise en place du programme de contrôle de la qualité des pipettes

- Pour se conformer aux bonnes pratiques de laboratoire, une procédure opératoire standard (SOP) pour le contrôle de la qualité des pipettes doit être définie

- Le SOP doit inclure la fréquence des tests, l'équipement de test, les critères d'acceptation, et les actions pour isoler les pipettes ne répondant pas aux critères

- Pour l'éducation continue du personnel de laboratoire, un programme de formation doit être mis en place

Les pipettes sont des outils de précision qui influencent considérablement les résultats des expériences scientifiques. Tous les laboratoires utilisant des pipettes devraient mettre en place un programme régulier non seulement pour la calibration et la maintenance, mais aussi pour les tests réguliers en laboratoire. Le programme doit être documenté et contrôlé avec des procédures opératoires standard pour le personnel de laboratoire.

Entreprises concernées :

Document protégé

Document uniquement accessible aux visiteurs connectés

Pas encore de compte ?

Inscrivez-vous

Déjà un compte ? Cliquez ici pour vous connecter

Connectez-vous