note d'application sur la calibration et les standards des pipettes

note d'application sur la calibration et l'entretien des pipettes selon les normes ISO

Contenu du document

Date de publication : 01 août 2018

Introduction

La calibration et l'entretien des pipettes sont cruciaux pour la précision des résultats de pipetage. Les normes ISO 8655 et ISO 17025 fournissent des lignes directrices sur la manière et les conditions de réalisation de ces calibrations.

Qu'est-ce que la calibration et la maintenance préventive ?

La calibration des pipettes est une composante fondamentale de la Bonne Pratique de Laboratoire (GLP) et des systèmes de qualité. Elle consiste à vérifier l'exactitude et la précision des pipettes.

La maintenance préventive inclut le nettoyage, la lubrification et le remplacement de pièces usées, et est recommandée au moins une fois par an.

Accréditation et systèmes de qualité

Les systèmes de qualité, tels que les accréditations ISO 9000 et ISO 17025, imposent des exigences spécifiques pour assurer la qualité du travail en laboratoire.

ISO 8655

L'ISO 8655 spécifie les exigences pour les pipettes et les laboratoires de calibration, incluant les conditions environnementales et les procédures à suivre.

ISO 17025

Ce standard précise les exigences pour la compétence des laboratoires de calibration, assurant la traçabilité et la fiabilité des résultats de calibration.

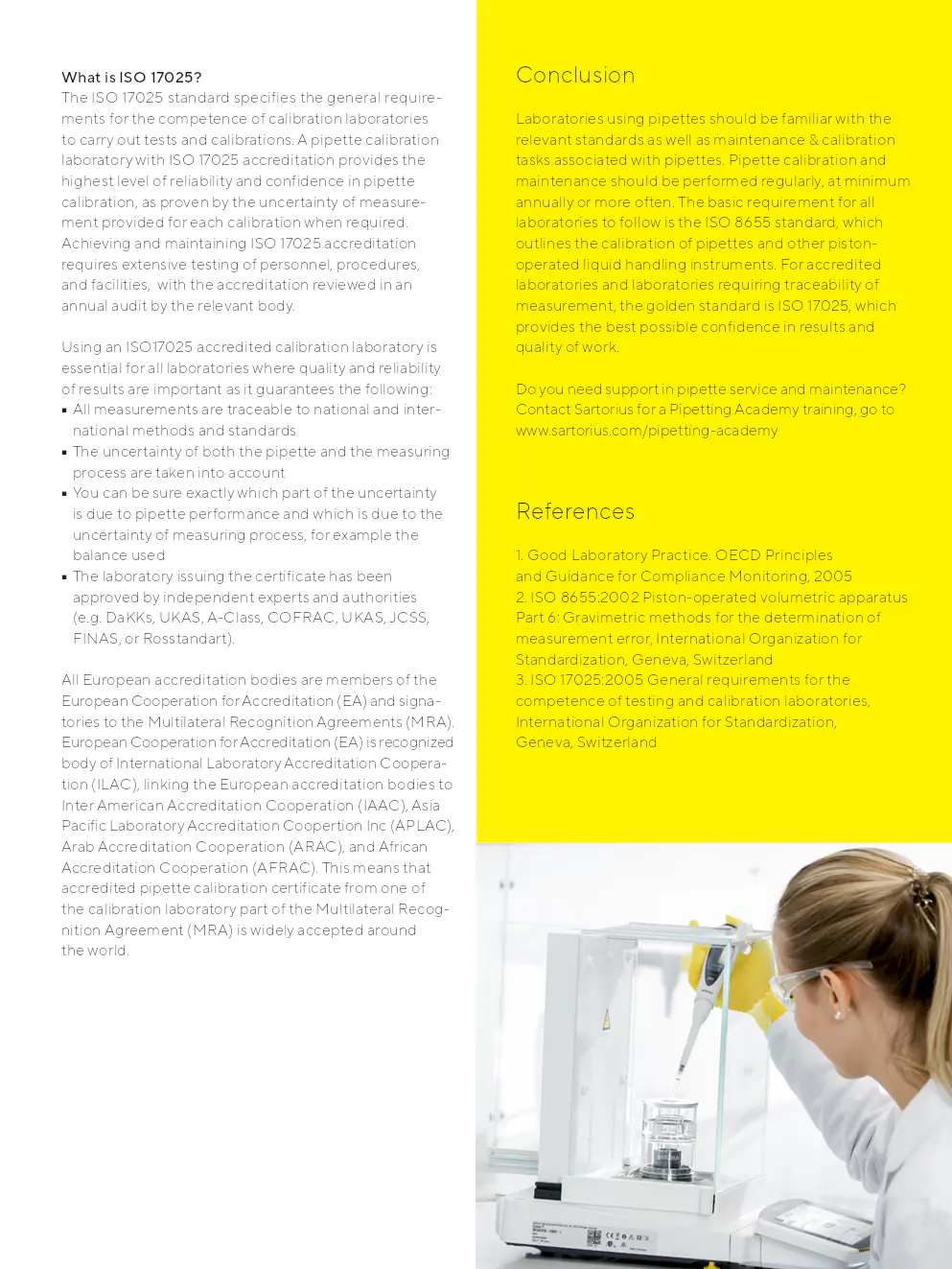

Conclusion

Les laboratoires doivent suivre les normes ISO 8655 et ISO 17025 pour garantir la précision et la fiabilité de leurs opérations de pipetage.

Pour plus d'informations et de soutien, contactez Sartorius pour une formation à l'Académie de Pipetage ici.

Références

- Bonne Pratique de Laboratoire. Principes et guide de l'OCDE, 2005

- ISO 8655:2002 Appareils volumétriques à piston

- ISO 17025:2005 Exigences générales pour la compétence des laboratoires de tests et de calibration

Contact :

- Allemagne : Sartorius Lab Instruments GmbH & Co. KG, Tel : +49 551 308 0

- USA : Sartorius Corporation, Tel : +1 631 254 4249, Toll-free : +1 800 635 2906

- Finlande et Baltiques : Sartorius Biohit Liquid Handling Oy, Tel : +358.9.755.951

Pour d'autres contacts, visitez www.sartorius.com

Les spécifications sont sujettes à modification sans préavis. Copyright Sartorius Lab Instruments GmbH & Co. KG, Septembre 2020.

Entreprises concernées :

Document protégé

Document uniquement accessible aux visiteurs connectés

Pas encore de compte ?

Inscrivez-vous

Déjà un compte ? Cliquez ici pour vous connecter

Connectez-vous