guide de conformité du pipetage selon les bonnes pratiques de laboratoire et de fabrication

guide pratique pour assurer la conformité aux bonnes pratiques de laboratoire et de fabrication dans le pipetage

Contenu du document

Introduction

Lors du développement ou du test de votre dispositif médical, la question se pose toujours : suivez-vous les méthodes pour les pratiques de laboratoire actuelles (cGLP) ou les pratiques de fabrication actuelles (cGMP) ? Dans ce guide pratique, nous avons compilé une liste que vous pouvez suivre pour vous assurer de votre conformité.

Les systèmes de qualité et les normes régissant le développement et la fabrication de produits pharmaceutiques, de dispositifs médicaux, ainsi que la façon dont les études cliniques sont menées, telles que GLP, GMP et la série ISO 9000, exigent que des procédures d'exploitation standard appropriées et techniquement valides (SOPs) soient suivies et qu'un processus de maintenance et de calibration régulier et documenté soit en place pour tous les instruments.

Dans ce guide, nous examinerons certains outils et principes qui peuvent aider à répondre à ces exigences exigeantes, en particulier en ce qui concerne vos pratiques de pipetage.

Principes de bonne pratique de laboratoire

- Organisation et personnel de l'installation de test

- Responsabilités de la direction de l'installation de test

- Appareils, matériaux et réactifs

- Les appareils utilisés dans une étude doivent être périodiquement inspectés, nettoyés, entretenus et calibrés selon des procédures d'exploitation standard. Les dossiers de ces activités doivent être conservés. La calibration doit, le cas échéant, être traçable aux normes nationales ou internationales de mesure.

Assurez-vous que les procédures d'exploitation standard sont suivies

Assurer que des SOPs appropriées et techniquement valides sont suivies est une exigence fondamentale pour la conformité GLP et GMP. En pratique, dans le laboratoire, cela signifie répéter les instructions de travail définies, sans déviations.

De nombreux autres processus sur le lieu de travail sont déjà totalement ou partiellement automatisés, et ce type d'assistance est également disponible pour le travail de laboratoire. Les pipettes électroniques, telles que la Sartorius Picus® NxT, peuvent être utilisées pour simplifier et accélérer les flux de travail en permettant l'intégration des SOPs à des protocoles de pipetage programmables. Une fois activé, le programme ajuste automatiquement les paramètres après chaque étape complétée.

Comment s'assurer que les instruments sont calibrés ?

L'utilisation de pipettes électroniques présente des avantages ergonomiques et améliore également les performances de pipetage et la répétabilité du dosage des personnels inexpérimentés et modérément expérimentés au niveau des experts.

Les sources d'erreurs de pipetage dépendantes de l'utilisateur peuvent s'accumuler jusqu'à une augmentation de 2 % de l'écart type, selon ISO8655. Ainsi, l'utilisation de pipettes électroniques élimine ces erreurs, car le mouvement du piston électronique assure la constance.

Quel est l'intervalle correct de calibration et d'entretien ?

Les laboratoires ont besoin d'un programme de contrôle de qualité des pipettes documenté pour répondre aux exigences réglementaires et aux exigences du système de qualité. L'utilisateur est responsable de la mise en place du programme, selon ISO 8655, une norme pour les appareils volumétriques à piston. Le programme doit décrire une routine de nettoyage et de test en laboratoire, l'intervalle de calibration et de maintenance, et comment assurer une éducation continue de votre personnel de laboratoire.

Êtes-vous sûr du volume ?

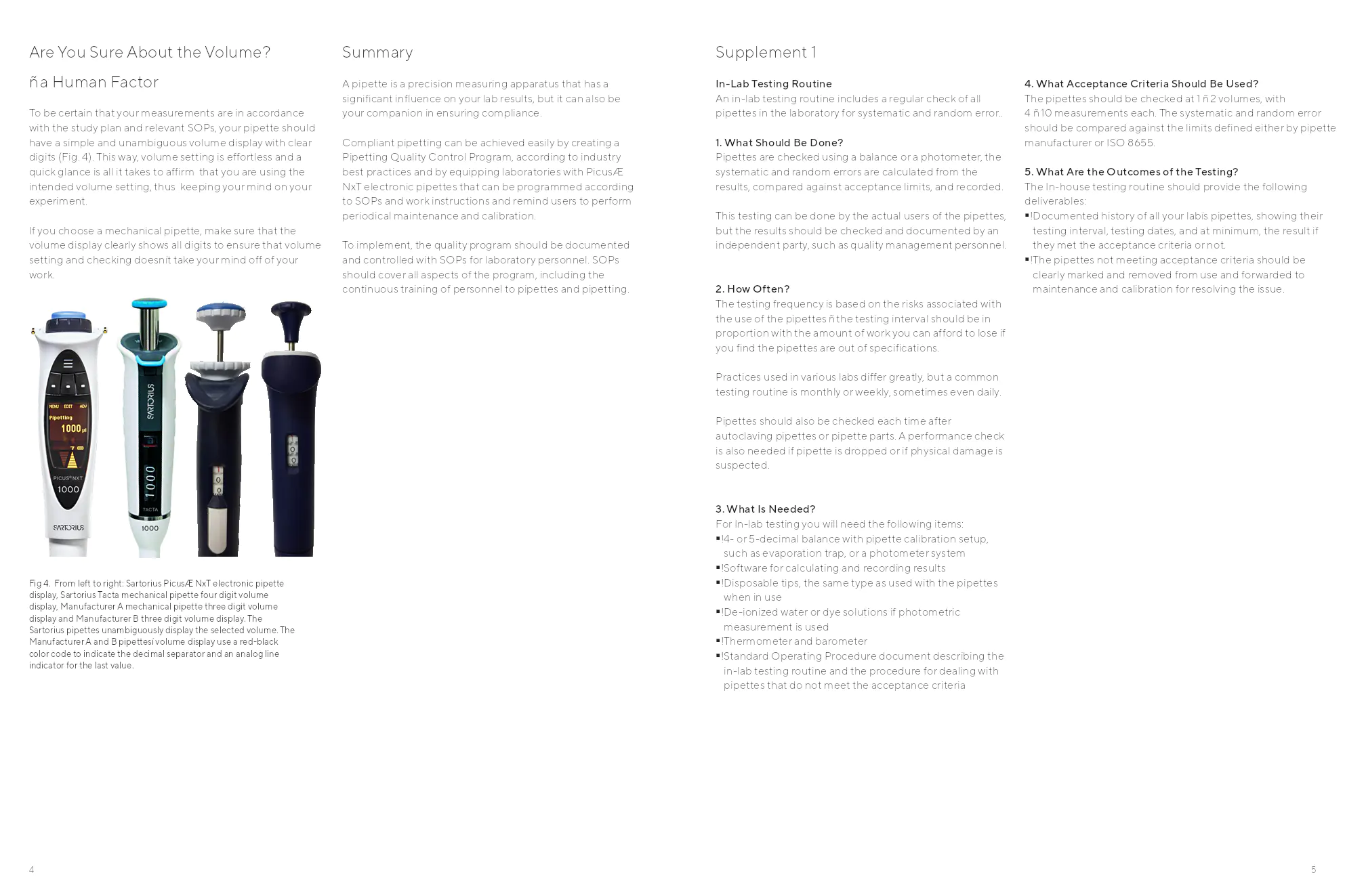

Pour être certain que vos mesures sont conformes au plan d'étude et aux SOPs pertinentes, votre pipette doit avoir un affichage de volume simple et sans ambiguïté avec des chiffres clairs. Si vous choisissez une pipette mécanique, assurez-vous que l'affichage du volume montre clairement tous les chiffres pour garantir que le réglage et la vérification du volume ne vous distraient pas de votre travail.

Résumé

Une pipette est un appareil de mesure de précision qui a une influence significative sur vos résultats de laboratoire, mais elle peut également être votre compagnon pour assurer la conformité. Le pipetage conforme peut être facilement réalisé en créant un programme de contrôle de qualité du pipetage, selon les meilleures pratiques de l'industrie et en équipant les laboratoires de pipettes électroniques Picus® NxT qui peuvent être programmées selon les SOPs et les instructions de travail et rappeler aux utilisateurs d'effectuer un entretien et une calibration périodiques.

Contact de ventes et de service

Pour plus de contacts, visitez www.sartorius.com

Sartorius Lab Instruments GmbH & Co. KG, Allemagne, Otto-Brenner-Strasse 20, 37079 Goettingen, Phone +49 551 308 0

Sartorius North America Inc., USA, 565 Johnson Avenue, Bohemia, NY 11716, Toll-Free +1 800 368 7178

Sartorius Biohit Liquid Handling Oy, Finlande, Laippatie 1, 00880 Helsinki, Phone +358 9 755 951, lhinfo.finland@sartorius.com

© 2020 Sartorius Lab Instruments GmbH & Co. KG. Specifications and design are subject to change without notice. Status: 04 | 2020

Entreprise(s) concernée(s) :

Document protégé

Document uniquement accessible aux visiteurs connectés

Pas encore de compte ?

Inscrivez-vous

Déjà un compte ? Cliquez ici pour vous connecter

Connectez-vous