note d'application sur la préparation de standards avec le système de dosage sartorius cubis msa

note d'application sur la préparation de standards avec le système de dosage sartorius cubis msa

Contenu du document

Date: June, 2017

Auteur: Holger Densow

Sartorius Lab Instruments GmbH & Co. KG, Otto-Brenner Str. 20, 37079 Göttingen, Germany

Email: holger.densow@sartorius.com

Abstract

Preparation of standards, also called reference samples, of known concentrations is a common routine procedure in analytical laboratories. Internal or external standards with very low concentrations are used in these laboratories for highly sensitive quantitative analytical methods to exactly determine the concentration of chemical components in samples using highly sensitive quantitative analytical procedures.

Introduction

The preparation of standards of known concentrations is a common routine procedure in analytical laboratories. Internal or external standards with very low concentrations are used in laboratories for highly sensitive quantitative analytical methods to determine the concentration of chemical compounds in samples accurately. External standards are separate samples used for comparison to test samples, whereas internal standards are added to the samples to be analyzed. Accurate concentration is crucial to prevent errors in determining unknown concentrations of compounds in samples.

Challenges in Manual Preparation

- The solvent volume required and the compound concentration desired are used to calculate the amount of a soluble compound to be weighed. Accuracy in weighing is challenging on high-resolution laboratory balances.

- If the amount weighed does not precisely match the target, the solvent quantity has to be adjusted, taking valuable time and potentially introducing errors.

- Recalculation involves considering various parameters such as desired concentration, purity, amount weighed, and molecular weight.

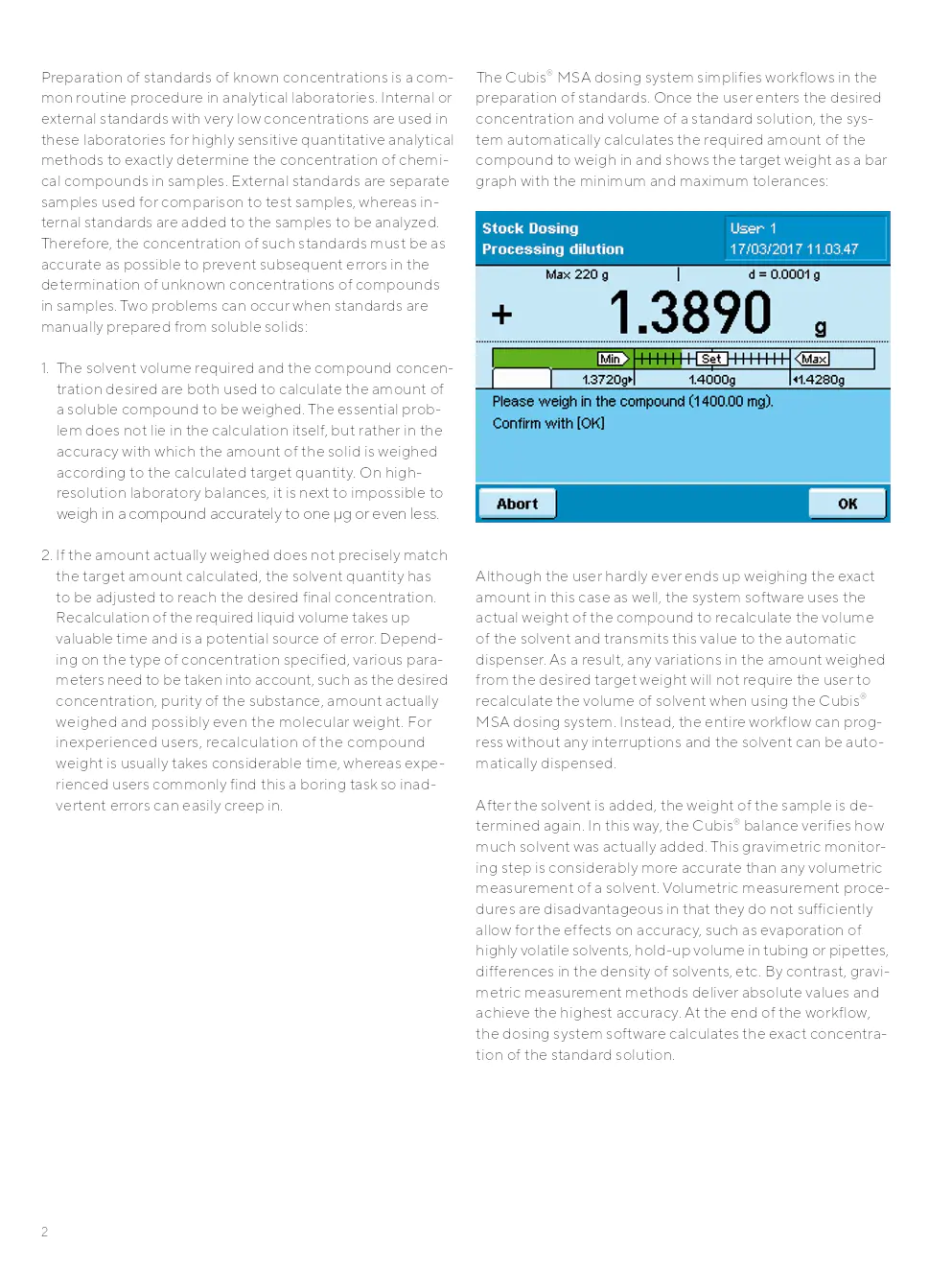

Sartorius Cubis® MSA Dosing System

The Cubis® MSA dosing system simplifies workflows by automatically calculating the required compound amount once the user inputs the desired concentration and volume. This system recalculates the solvent volume based on actual weight, preventing workflow interruptions.

Advantages of Gravimetric Monitoring

Gravimetric monitoring is more accurate than volumetric measurement, which is affected by factors such as evaporation and density differences. The dosing system software calculates the exact concentration of the standard solution at the workflow's end.

Benefits Over Automatic Systems

The semi-automatic system provides higher flexibility, saves time, and reduces costs compared to fully automatic dispensing systems. It is suitable for laboratories with a low to medium number of standards.

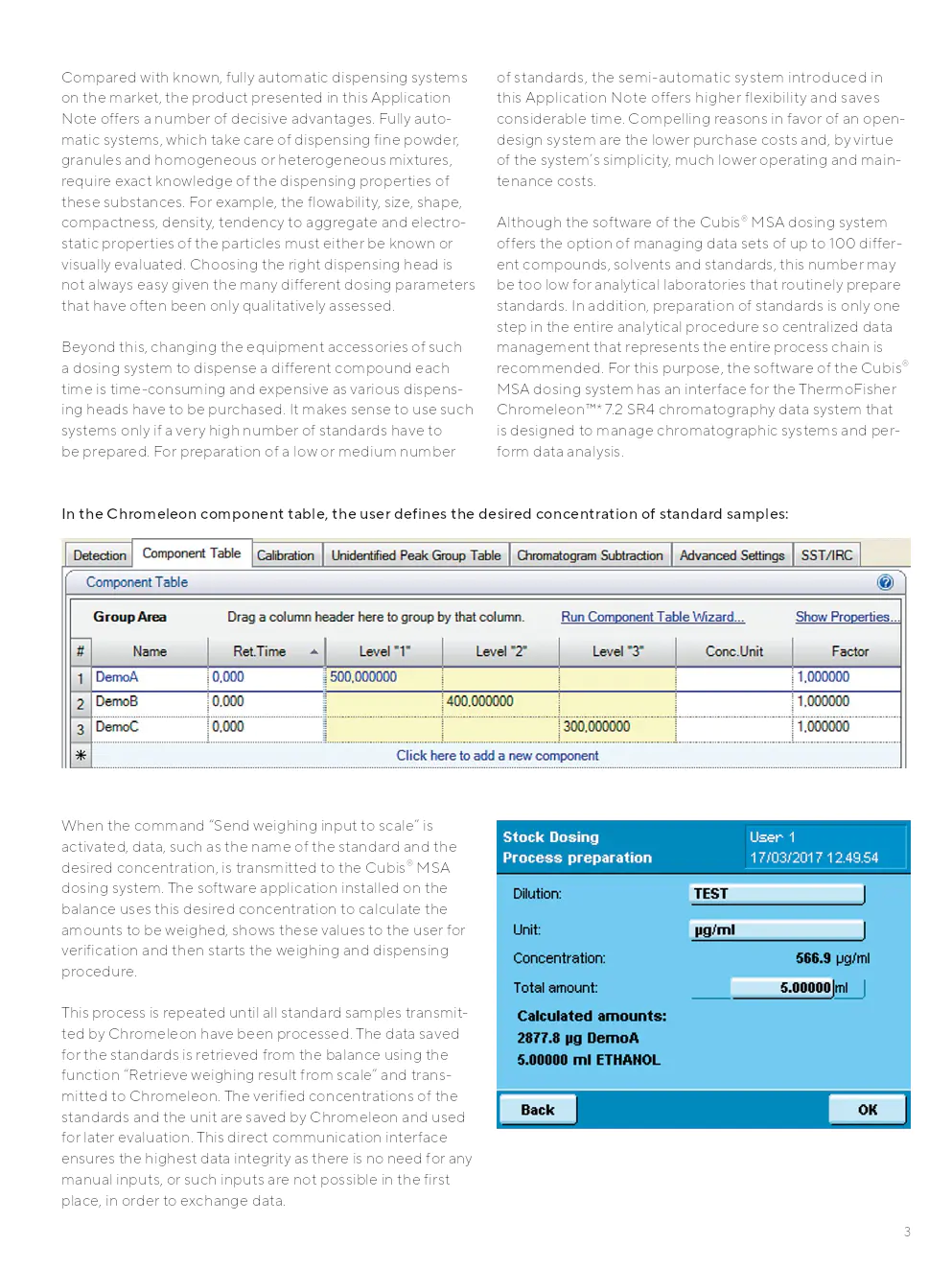

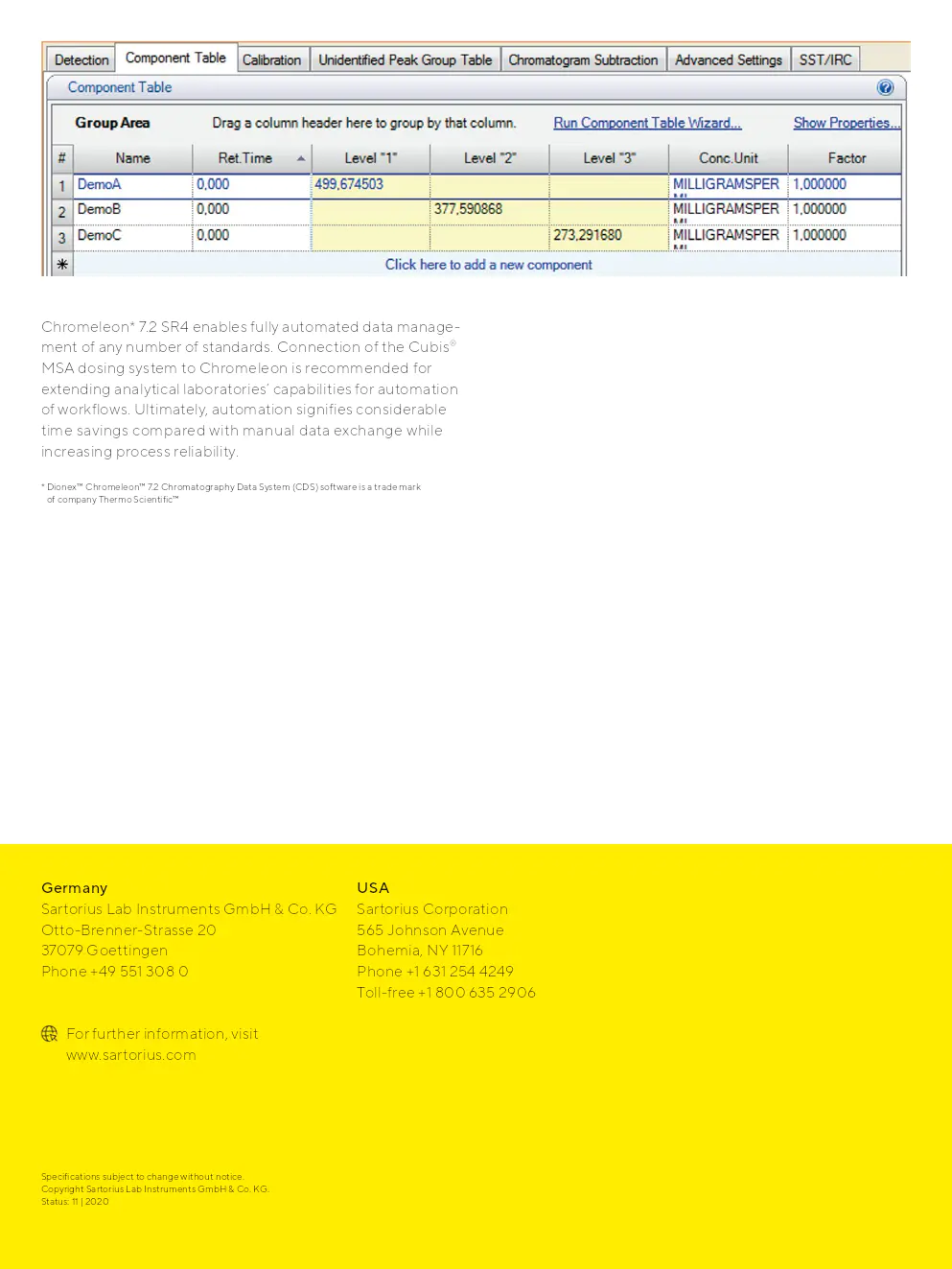

Data Management with Chromeleon

The software of the Cubis® MSA dosing system interfaces with ThermoFisher Chromeleon™ 7.2 SR4, allowing centralized data management. This ensures data integrity and facilitates the extension of analytical laboratories’ capabilities for workflow automation.

Contact Information

Germany: Sartorius Lab Instruments GmbH & Co. KG, Otto-Brenner-Strasse 20, 37079 Goettingen

Phone: +49 551 308 0

USA: Sartorius Corporation, 565 Johnson Avenue, Bohemia, NY 11716

Phone: +1 631 254 4249

Toll-free: +1 800 635 2906

For further information, visit www.sartorius.com

Specifications subject to change without notice.

Copyright Sartorius Lab Instruments GmbH & Co. KG. Status: 11 | 2020

Entreprises concernées :

Document protégé

Document uniquement accessible aux visiteurs connectés

Pas encore de compte ?

Inscrivez-vous

Déjà un compte ? Cliquez ici pour vous connecter

Connectez-vous