white paper sur les innovations en microbalances cubis ii

étude sur les innovations et applications des microbalances cubis ii

Contenu du document

Introduction

Date: July 26, 2021

Keywords: Lab weighing, Balances, Microbalances, Ultra-Microbalances, Cubis® II

Auteurs

Dr. Thomas Pertsch, Dr. Holger Densow

Sartorius Lab Instruments GmbH & Co. KG, Otto-Brenner-Straße 20, 37079 Goettingen

Abstract

Micro- and ultra-microbalances are very precise measurement devices with a scale interval of 0.1 ?g or 1 ?g that are used to weigh very small sample amounts. Obtaining reliable weighing results with these balances requires special considerations regarding the installation site in addition to optimized ergonomics and technical controls. Sartorius’s innovative micro- and ultra-microbalances offer both accuracy and ease of use for routine measurement.

Description des microbalances et ultramicrobalances

It is fascinating that we can use micro- and ultra-microbalances to weigh sample amounts so small that they are invisible to the naked eye. Considering the conventional visual range of 25 cm, some people can still distinguish structures with a distance of 150 ?m. This corresponds to a viewing angle of approximately 2 arc minutes. Others can only distinguish structures at a distance of 300 ?m or 4 arc minutes. On average, the healthy human eye can resolve two independent structures at a distance of 200 ?m (the normal visual acuity of the human eye at a comfortable viewing distance (d) of 12 inches (appr. 30 cm) is 0.00349 inch (appr. 89 ?m) with ? = 1/60 of a degree).

A small particle with a density of 2 g/cm3 and a weight equal to the smallest scale interval of a microbalance has a diameter that is less than 100 ?m. An ultra-microbalance with a readability of 0.1 ?g can accurately determine the weight of a particle with a diameter of only 45 ?m. So even if the particle size is below the visual acuity of the human eye, the weight can be accurately determined.

Applications typiques

Typical areas of application for the micro- and ultra-range weight measurement are filter weighing (filter particulate matter and residual dirt analysis), pipette calibration, measuring the coating of medical products (stent weighing), pesticide analysis, measuring the incineration or drying of chemicals or finished goods and the dispensing of medical drugs. Micro- and ultra-microbalances therefore play an essential role in R&D and industrial quality control laboratories in the automotive, pharmaceutical, chemical, food, mining industry, and medical device manufacturing.

Caractéristiques techniques et innovations

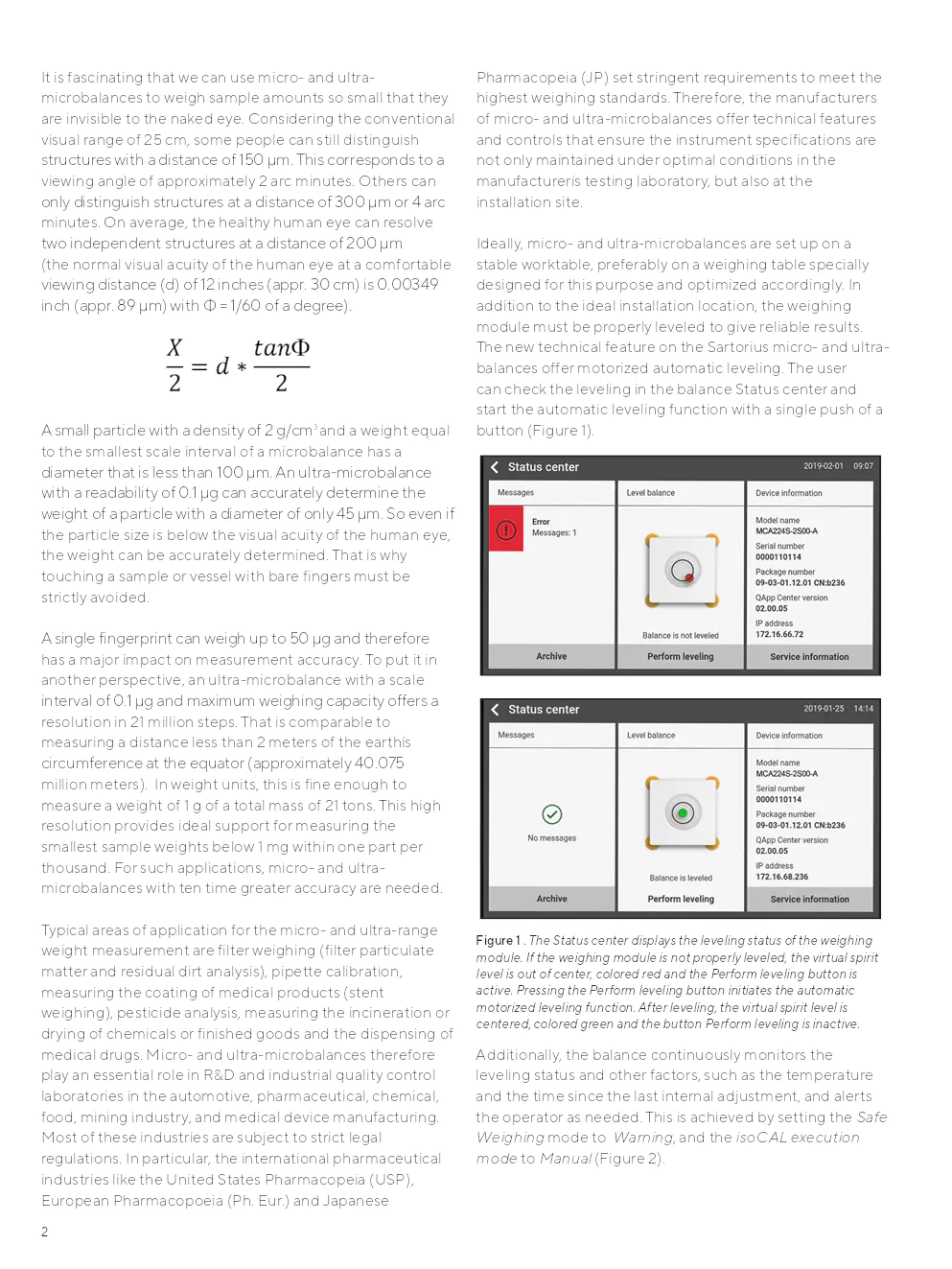

Ideally, micro- and ultra-microbalances are set up on a stable worktable, preferably on a weighing table specially designed for this purpose and optimized accordingly. In addition to the ideal installation location, the weighing module must be properly leveled to give reliable results. The new technical feature on the Sartorius micro- and ultra balances offer motorized automatic leveling. The user can check the leveling in the balance Status center and start the automatic leveling function with a single push of a button (Figure 1).

Facteurs environnementaux

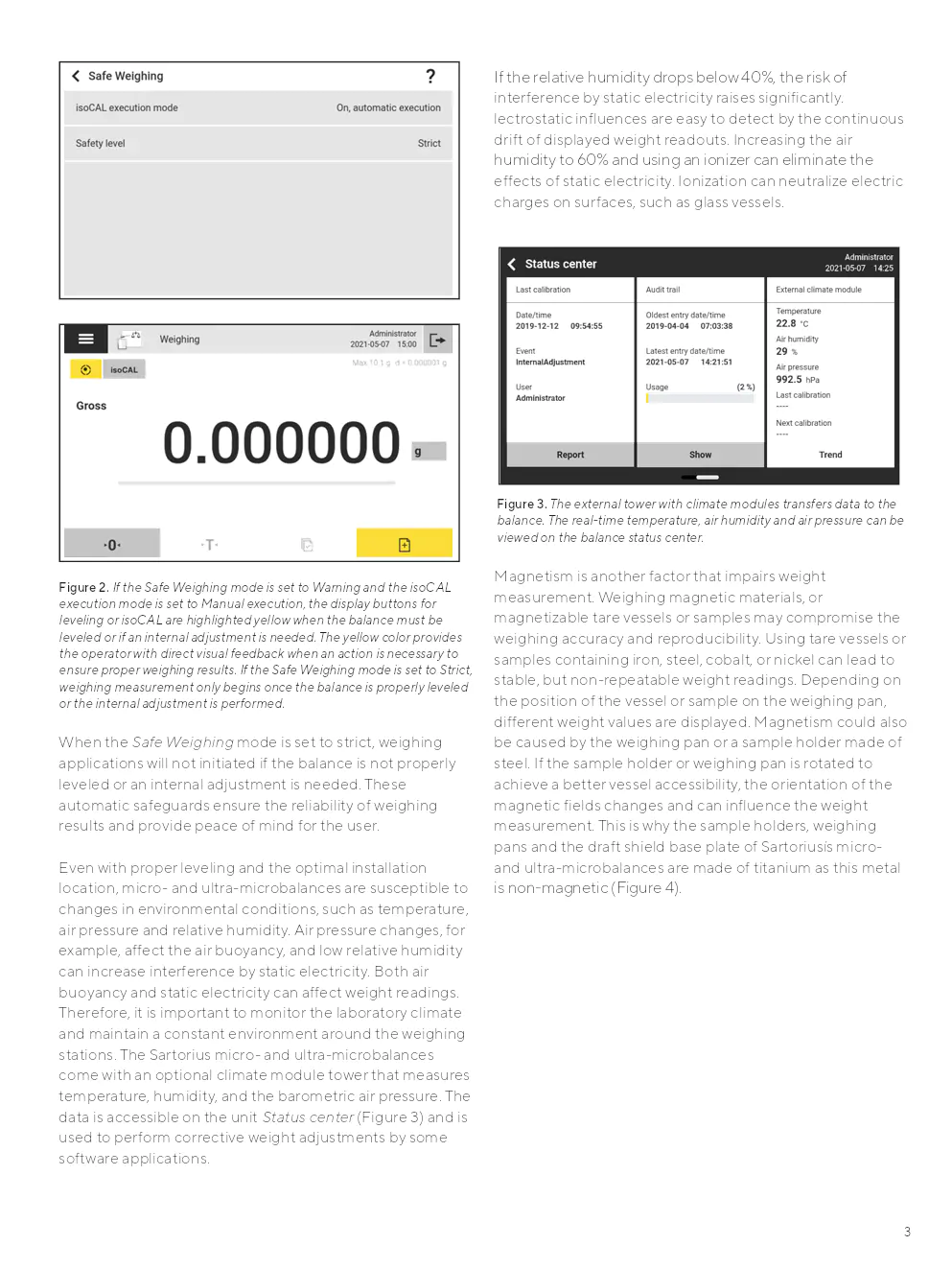

Additionally, the balance continuously monitors the leveling status and other factors, such as the temperature and the time since the last internal adjustment, and alerts the operator as needed. This is achieved by setting the Safe Weighing mode to Warning, and the isoCAL execution mode to Manual (Figure 2).

If the relative humidity drops below 40%, the risk of interference by static electricity raises significantly. Electrostatic influences are easy to detect by the continuous drift of displayed weight readouts. Increasing the air humidity to 60% and using an ionizer can eliminate the effects of static electricity. Ionization can neutralize electric charges on surfaces, such as glass vessels.

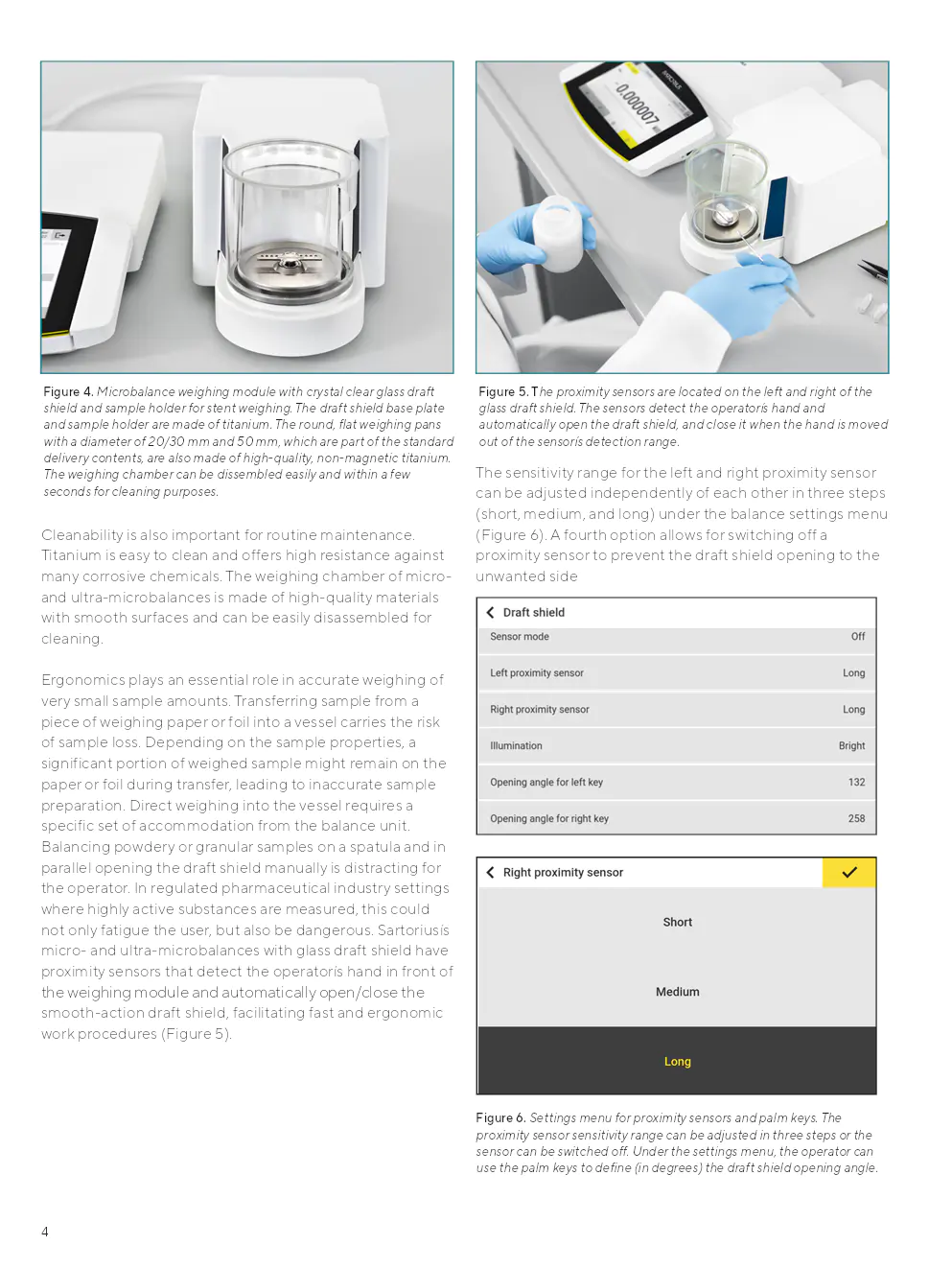

Magnetism is another factor that impairs weight measurement. Weighing magnetic materials, or magnetizable tare vessels or samples may compromise the weighing accuracy and reproducibility. Using tare vessels or samples containing iron, steel, cobalt, or nickel can lead to stable, but non-repeatable weight readings. Depending on the position of the vessel or sample on the weighing pan, different weight values are displayed. Magnetism could also be caused by the weighing pan or a sample holder made of steel. If the sample holder or weighing pan is rotated to achieve a better vessel accessibility, the orientation of the magnetic fields changes and can influence the weight measurement. This is why the sample holders, weighing pans and the draft shield base plate of Sartorius’s micro- and ultra-microbalances are made of titanium as this metal is non-magnetic (Figure 4).

Ergonomie et confort de travail

Ergonomics plays an essential role in accurate weighing of very small sample amounts. Transferring sample from a piece of weighing paper or foil into a vessel carries the risk of sample loss. Depending on the sample properties, a significant portion of weighed sample might remain on the paper or foil during transfer, leading to inaccurate sample preparation. Direct weighing into the vessel requires a specific set of accommodation from the balance unit.

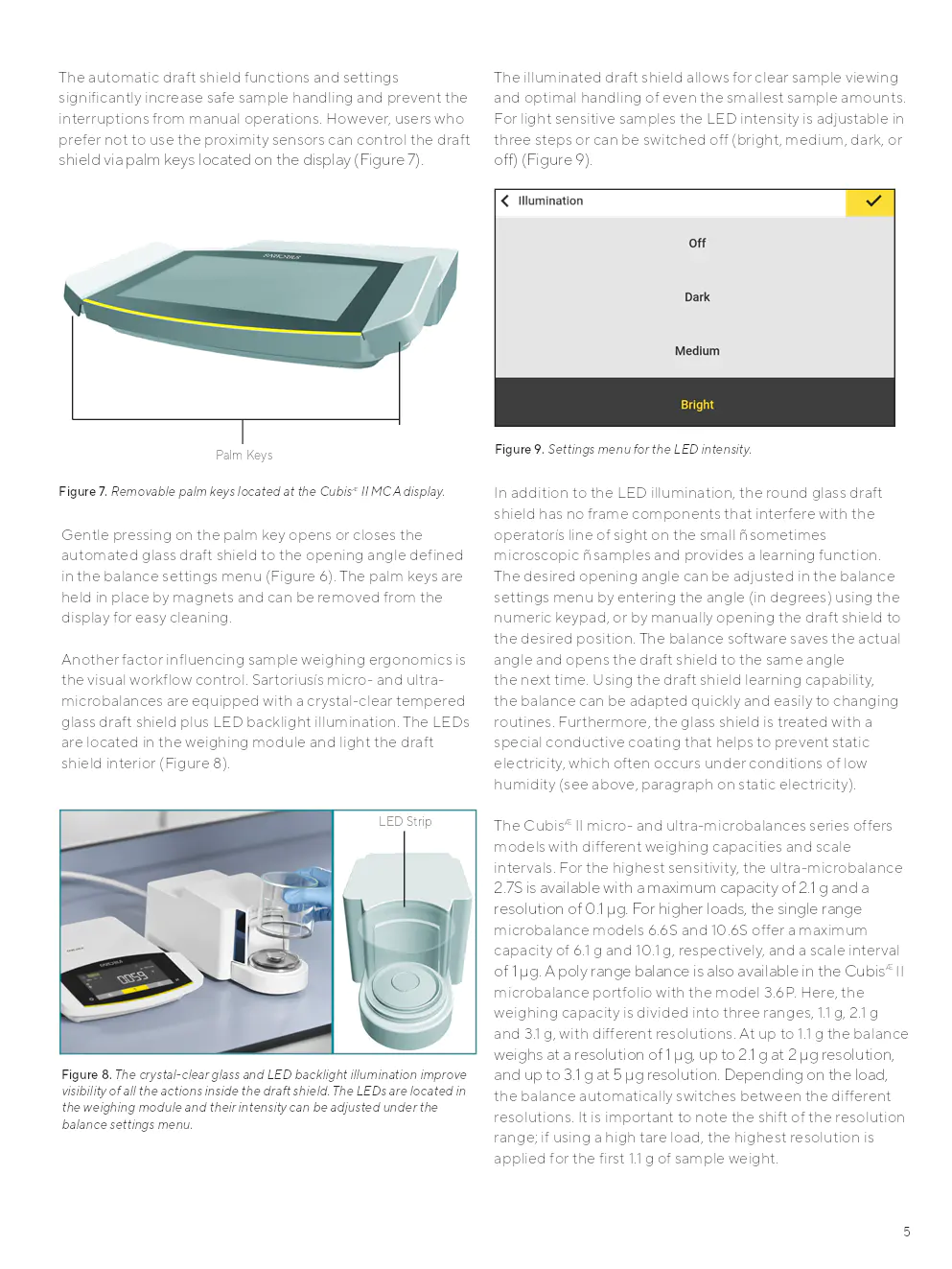

The sensitivity range for the left and right proximity sensor can be adjusted independently of each other in three steps (short, medium, and long) under the balance settings menu (Figure 6). A fourth option allows for switching off a proximity sensor to prevent the draft shield opening to the unwanted side.

Applications avancées et intégration logicielle

Cubis® II MCA micro- and ultra-microbalances have approximately sixty preinstalled weighing applications and extended functions in the QApp Center. In the QApp Center, applications are grouped by topic into different packages. The Essentials package offers thirteen different license-free weighing applications, covering basic weighing applications. Other applications or extended functions are grouped into five additional packages (Pharma, Advanced Applications, Utilities, Connectivity, and Specials). Except for the Specials software application, the remaining four software packages can be factory licensed at the time of purchase. Software applications and extended functions in these packages offer optimal support and technical controls for 21 CFR part 11 (audit trail, electronic signatures and user management) and USP chapter 41 (determination and monitoring of the minimum sample weight) or EURAMET cg-18 compliance (measurement uncertainty) and for guided weighing applications for filter or stent weighing (filter particulate matter, backweighing).

Contact

Germany: Sartorius Lab Instruments GmbH & Co. KG, Otto-Brenner-Strasse 20, 37079 Goettingen. Phone +49 551 308 0

USA: Sartorius Corporation, 565 Johnson Avenue, Bohemia, NY 11716. Phone +1 631 254 4249, Toll-free +1 800 635 2906

Entreprises concernées :

Questions liées :

Document protégé

Document uniquement accessible aux visiteurs connectés

Pas encore de compte ?

Inscrivez-vous

Déjà un compte ? Cliquez ici pour vous connecter

Connectez-vous