note d'application sur comment éviter les contaminations lors de la pipette

document sur la prévention des contaminations dans le pipetage

Contenu du document

Introduction

Prévenir la contamination dans le pipetage est primordial pour obtenir des résultats fiables. Cela nécessite l'identification des mécanismes potentiels de contamination afin de pouvoir les traiter. Les aérosols, suspensions de particules solides ou liquides dans un gaz, sont formés dans de nombreuses activités de laboratoire telles que le pipetage avec des pipettes à déplacement d'air, et représentent la principale source de contamination. Ils peuvent pénétrer dans le corps de la pipette lorsqu'on utilise des embouts sans filtre, contaminant ainsi les échantillons suivants. Un rythme de pipetage lent et soigneux aide à minimiser la formation d'aérosols. Ce document traite des trois types de contamination qui proviennent du pipetage : la contamination pipette-échantillon, l'échantillon-vers-pipette, et échantillon-à-échantillon.

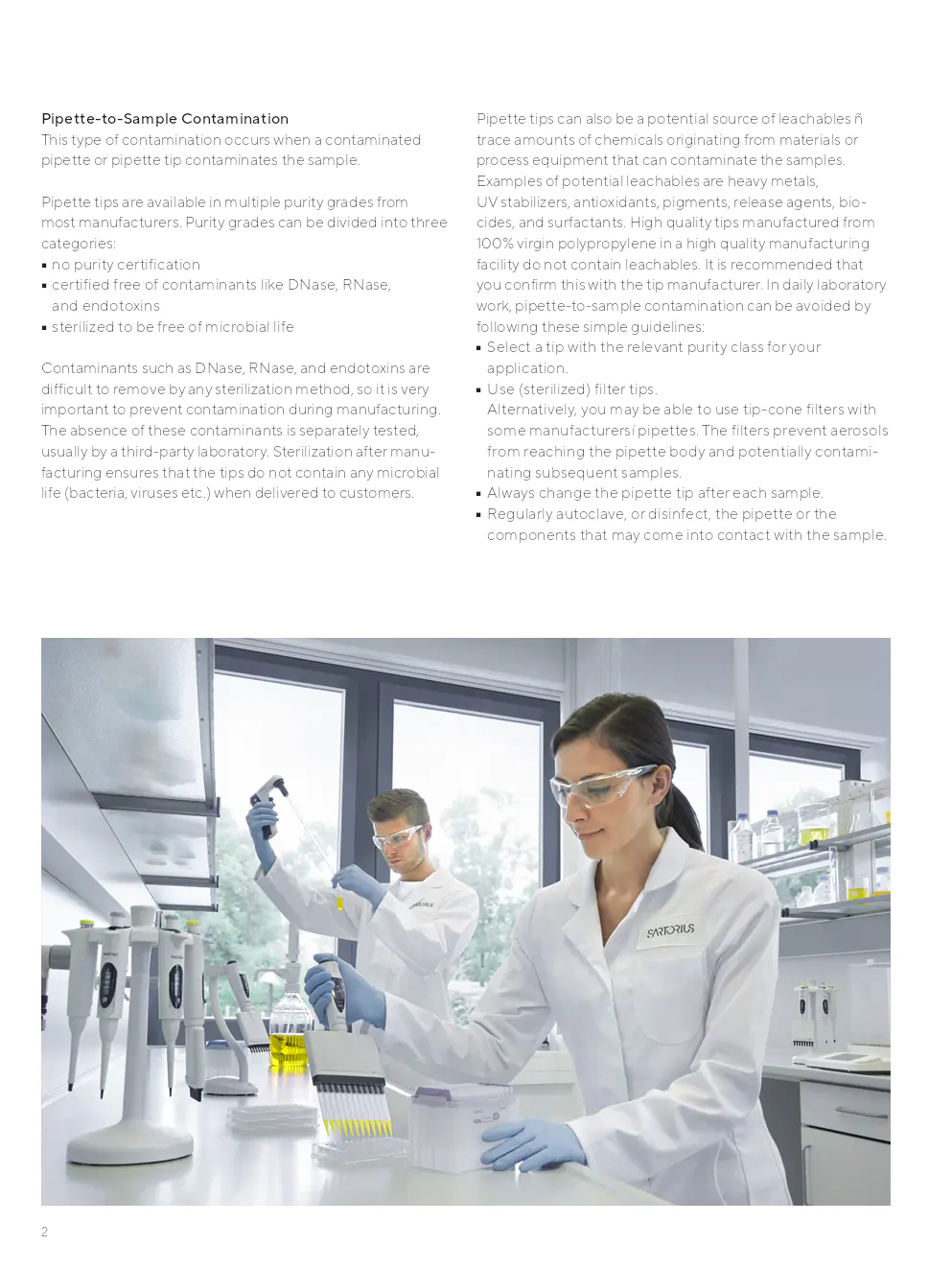

Contamination pipette-échantillon

Ce type de contamination survient lorsqu'une pipette ou un embout contaminé contamine l'échantillon.

- Les embouts de pipette sont disponibles en plusieurs grades de pureté provenant de la plupart des fabricants. Les grades de pureté peuvent être divisés en trois catégories : sans certification de pureté, certifiés exempts de contaminants comme la DNase, la RNase et les endotoxines, et stérilisés pour être exempts de vie microbienne.

- Les contaminants tels que la DNase, la RNase, et les endotoxines sont difficiles à éliminer par toute méthode de stérilisation, donc il est très important de prévenir la contamination pendant la fabrication. L'absence de ces contaminants est testée séparément, généralement par un laboratoire tiers. La stérilisation après la fabrication garantit que les embouts ne contiennent aucune vie microbienne lorsqu'ils sont livrés aux clients.

- Leachables potentiellement présents dans les embouts de qualité inférieure incluent des métaux lourds, des stabilisateurs UV, des antioxydants, des pigments, agents de démoulage, biocides, et tensioactifs. Il est recommandé de confirmer avec le fabricant que les embouts de haute qualité fabriqués à partir de polypropylène vierge ne contiennent pas de leachables.

- Pour éviter la contamination pipette-échantillon, suivez ces simples consignes: sélectionnez un embout avec la classe de pureté pertinente, utilisez des embouts filtrants stérilisés, changez toujours l'embout après chaque échantillon, autoclavez ou désinfectez régulièrement la pipette ou les composants qui peuvent entrer en contact avec l'échantillon.

Contamination échantillon-vers-pipette

Ce type de contamination se produit lorsque le liquide pipeté ou ses aérosols pénètrent dans le corps de la pipette.

- Pour minimiser le risque de contamination échantillon-vers-pipette, libérez toujours le bouton de poussée lentement pour éviter la formation d'aérosols et les éclaboussures de liquide incontrôlées dans l'embout de pipette.

- Tenez la pipette en position verticale lors du pipetage et stockez-la en position verticale pour empêcher les liquides de s'écouler dans le corps de la pipette.

- Utilisez des embouts filtrants pour empêcher le transfert d'aérosol de l'échantillon dans le corps de la pipette; alternativement, des filtres peuvent être utilisés sur les cônes d'embout de pipette.

Contamination échantillon-à-échantillon

La contamination échantillon-à-échantillon (ou contamination croisée) se produit lorsque des résidus d'aérosol ou de liquide d'un échantillon sont transférés au suivant. Cela peut se produire, par exemple, lorsque les mêmes embouts de pipette sont utilisés plusieurs fois.

- Pour éviter la contamination croisée: utilisez des embouts filtrants pour empêcher le transfert d'aérosol de l'échantillon dans le corps de la pipette, et à nouveau vers l'échantillon suivant; changez toujours l'embout de pipette après chaque échantillon.

- Si vous suspectez une contamination de la pipette, autoclavez ou désinfectez la pipette selon les instructions du fabricant.

Définitions

- Décontamination: Toute activité qui réduit la charge microbienne pour prévenir la contamination, incluant les méthodes de stérilisation, désinfection et antisepsie.

- Stérilisation: Destruction de toute vie microbienne, y compris les endospores bactériennes.

- Autoclavage: Méthode efficace de stérilisation par la chaleur humide, appliquant de la vapeur chaude, pressurisée et saturée.

- Désinfection: Élimination de quasiment tous les micro-organismes pathogènes pour réduire la contamination microbienne à un niveau acceptable.

- Antisepsie: Application de produit chimique antimicrobien sur les tissus vivants pour détruire micro-organismes.

- DNase: Enzyme puissante qui dégrade l'ADN.

- RNase: Enzyme puissante qui catalyse la dégradation de l'ARN.

- Endotoxines: Lipopolysaccharides constituant la membrane externe de certaines bactéries Gram-négatives, provoquant fièvre et perturbation de la croissance des cultures cellulaires.

Entreprises concernées :

Document protégé

Document uniquement accessible aux visiteurs connectés

Pas encore de compte ?

Inscrivez-vous

Déjà un compte ? Cliquez ici pour vous connecter

Connectez-vous